CFR 3D Printing Service

3D printing with continuous fiber reinforcements. Strength

of machined parts & in your hands faster.

All uploads are secure and confidential.

CFR 3D Printing Service

3D printing with continuous fiber reinforcements. Strength of machined parts & in your hands faster.

Get instant quoteAll uploads are secure and confidential.

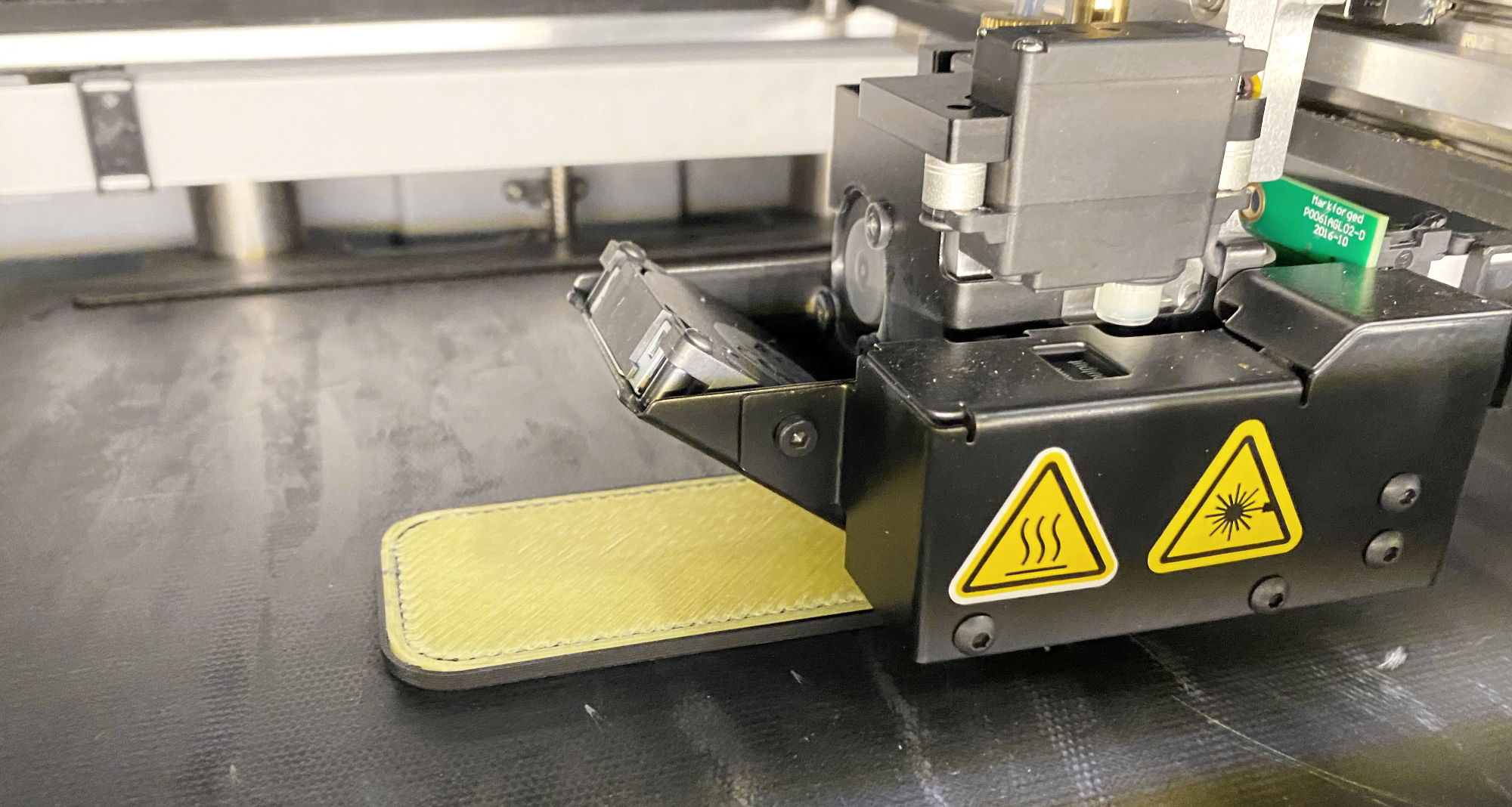

Continuous Fiber Reinforcement

CFR process starts with FDM 3D printing, which forms the outer shell and infill of the part using a nylon composite, typically a thermoplastic filled with short-strand chopped carbon fibers. A secondary nozzle is then used to lay long-strand continuous fibers to reinforce the part, similar to rebar in concrete.

Capabilities & Standards

Requirement

Capability

Maximum Build Size:

330 x 270 x 200 mm (12.99" x 10.63" x 7.87")

Dimensional Accuracy:

± 0.5% with a lower limit on ± 0.5 mm (0.0196")

Layer Height (with Fiber):

100-125 µm

Layer Height (no Fiber):

50-200 µm

Percent Infill:

28-55% or 100%

Standard Lead Times:

1 Day

Printing Media:

Plastics/fiber reinforcements

Internal Part Geometry:

Closed cell infill with continuous fiber reinforcement

Post Processing:

Support material is removed such that the supported surface has a consistent finish

CFR Design Guidelines

The table below is a summary of the recomemended minimum size for the most commonly encountered features in CFR 3D printing.

Feature

Minimum Size

Unsupported Walls:

0.8 mm (0.0315")

Supported Walls:

0.8 mm (0.0315")

Minimum Feature:

2.0 mm (0.0787")

Hole Diameter:

2.0 mm (0.0787")

Fiber Reinforced Walls:

3.0 mm (0.0787")