CNC Turning Service

Upload CAD files, receive an instant CNC Turning quote,

and get your parts into production in minutes.

All uploads are secure and confidential.

CNC Turning Service

Upload CAD files, receive an instant CNC Turning quote, and get your parts into production in minutes.

Get instant quoteAll uploads are secure and confidential.

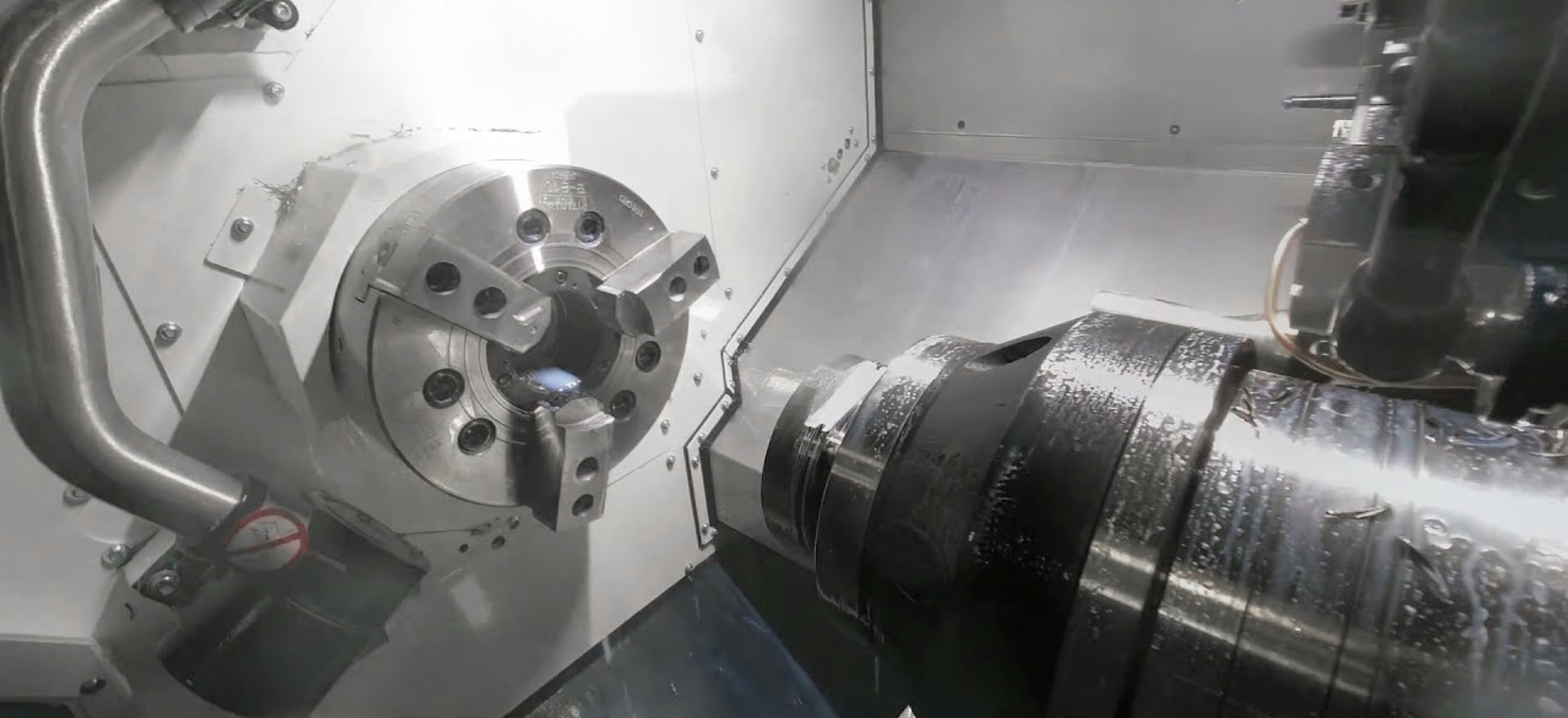

CNC Turning

CNC Turning is a subtractive manufacturing process in the part is rotated while a cutting tool is fed to the piece, removing material to create a finished part. It is primarily used to manufacture parts that are cylindrical in nature and can provide a smooth surface finish.

Capabilities & Standards

Requirement

Capability

- Turning - Ø8" x 10"

- As Machined - sharp edges are removed and tool marks are visible

- Bead Blast - sharp edges are removed and provides a matte finish

- Anodize (Type II)

- Hard Anodize (Type III)

- Chromate Conversion Coating

- Flash Chrome

- Nickel Plating

- Gold Plating

- Silver Plating

- Passivation

- Helicoils

- Keyserts

- Press Fit Pins

- Standard - 10 Business Days

- Expedite - 1-5 Business Days

Possible Features

The table below outlines the specific features that can be achieved with our CNC Turning capabilities.

Feature

Capability

- UN

- ISO

- STI

- BSPT

- BSPP

- NPT

- ACME

- Custom

- Ø 0"-0.75" - Maximum depth of ØX12

- Ø 0.75"-1.5" - Maximum depth of ØX6

- Ø 1.5"-2" - Maximum depth of ØX4

- Yes - All our turning centers are equiped with milling capabilities.

- Diamond

- Straight

- Helical

- 3-Axis Surfacing

CNC Turning Materials

Other materials are available upon requestTolerances

When no 2D Drawings are supplied, we follow ISO 2768 standards. Two options are available via our instant quote platform.

Tighter tolerances are available upon requestNominal Size (in)

Medium (ISO 2768-m)

Fine (ISO 2768-f)

0.020" ≤ x ≤ 0.118"

±0.004"

±0.002"

0.118" < x ≤ 0.236"

±0.004"

±0.002"

0.236" < x ≤ 1.181"

±0.008"

±0.004"

1.181" < x ≤ 4.724"

±0.012"

±0.006"

4.724" < x ≤ 15.748"

±0.020"

±0.008"

15.748" < x ≤ 39.370"

±0.032"

±0.012"

Medium (ISO 2768-m)

Nominal Size (in)

Tolerance (in)

0.020" ≤ x ≤ 0.118"

±0.004"

0.118" < x ≤ 0.236"

±0.004"

0.236" < x ≤ 1.181"

±0.008"

1.181" < x ≤ 4.724"

±0.012"

4.724" < x ≤ 15.748"

±0.020"

15.748" < x ≤ 39.370"

±0.032"

Fine (ISO 2768-f)

Nominal Size (in)

Tolerance (in)

0.020" ≤ x ≤ 0.118"

±0.002"

0.118" < x ≤ 0.236"

±0.002"

0.236" < x ≤ 1.181"

±0.004"

1.181" < x ≤ 4.724"

±0.006"

4.724" < x ≤ 15.748"

±0.008"

15.748" < x ≤ 39.370"

±0.012"

Quality Assurance

- Certificate of Conformance (CoC) included in every order. Inspection reports are available upon request.

- ITAR Registered Manufacturer.

- NDA agreement signature upon request.

- ISO 9001 compliant, certified by March 2025.

- All CNC-machined parts inspected using hand metrology, Coordinate Measuring Machine (CMM), and/or Vision Measurement System (VMS).